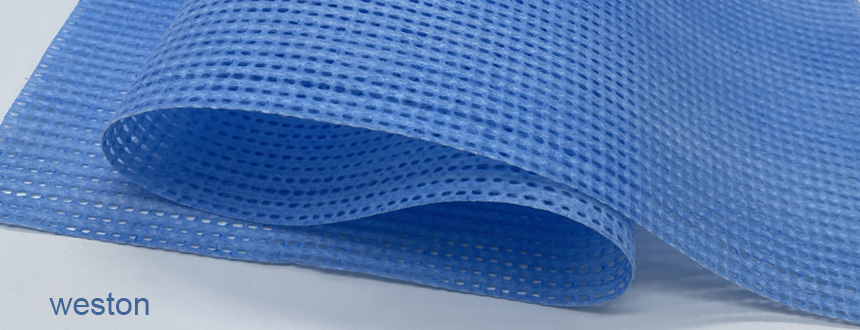

Solid color quat mesh wipes for food service

Advantage:

- The product reaches food grade, is odorless, will not cause harm to human body, product and environment, and is healthy and safe;

- Can directly and efficiently remove dust, oil stains, dust, stains, etc. are easy to use;

- No dust, no secondary pollution to the product;

- High-quality performance, not easy to fall off, no slag;

- 100% biodegredable, good for our environment;

- Super absorbent for oil and grease;

- Versatile colors to mark different function area, such as blue quat, yellow quat, green quat, pink quat, etc;

- Safe to food dealing process;

Description:

- Material: 100% viscose spunlace nonwoven fabric.

- Technic: spunlacing technology

- Main application: food service, food processing, food manufacturing, etc

- Gram weight: 70-98 grams

- Mesh type: 8 mesh, 10mesh, 12 mesh, 14 mesh, 16mesh, 18mesh, 22 mesh

- Coloring: solid color and color fast, non-fading

What properties must a solid color quat mesh wipes for food service have?

- The unique plant fiber material will not scratch the surface of the object;

- Excellent water and oil absorption performance, under the unit gram weight, the water absorption and oil absorption are respectively 68% and 75% higher than those of traditional wipes;

- Soft, strong absorption, can quickly absorb several times its own weight of liquid;

- Extremely low chip removal and not easy to leave dust after wiping, meeting the needs of the process environment;

- Colorfast, silicone-free, to ensure process safety;

- Has high tensile and wear-resistant strength;

- Anti-bacteria;

Test report of solid color quat mesh wipes for food service we have:

- The food wipes passed the following test indicators:

- EU RoHS Directive 2011/65/EU Annex II Amendment Directive (EU) 2015/863 limit requirements, including cadmium, lead, mercury, hexavalent chromium, polybrominated biphenyls (PBBs), polybrominated diphenyl ethers (PBDEs), etc. test;

- Pass the test of coliform/total colony/Staphylococcus aureus/fungus/Pseudomonas aeruginosa/hemolytic streptococcus;

- Passed silicon-free (Si) detection;

- Passed the testing required by the US FDA 21 CFR 177.1520 and 21CFR 176.170 and other regulations;

- Guidelines for color separation management of rags

1.1 Color separation area selection

Color can be divided according to the raw area, the cooked area, the table in front of the hall, the cleaning of equipment and facilities, and the toilet.

1.2 Cleaning of the rags

1) The dirty rags after use should be uniformly stored in a fixed area. It is recommended to distinguish them according to the objects of different cleanliness, especially the rags used in the bathroom need to be cleaned separately from other areas.

2) Soak it in detergent (such as dishwashing liquid) for a few minutes, put it in the washing machine and set it to wash and dehydrate for 30 minutes. For the rag with heavy oil stains on the white bottom, if there are residual stains after cleaning, you can use bleach to soak it first and then bleach it. Then enter the washing machine to clean.

3) The cleaned rags should be stored separately according to the different areas of 2.1.

1.3 Storage of rags

1) Clean rags after cleaning: use plastic turnover buckets or fresh-keeping boxes with complete markings for storage. Generally, it is advisable to store 10-20 rags.

2) Dirty rags (or rags to be cleaned): use plastic turnover buckets or fresh-keeping boxes with complete marks for unified storage. Do not litter or place them randomly.