Lyocell spunlace nonwovens are made of lyocell fibers. Lyocell fibers are degradable fibers and are 100% biodegradable.

Lyocell fiber is known as the environmentally friendly fiber of the 21st century. It is made of conifer-based wood pulp, water and solvent amine oxide mixed and heated to complete dissolution. No derivatives and chemical effects are produced during the dissolution process. After removal of impurities, it is directly spun. Its molecular structure is simple carbohydrates. compound. Its production process does not pollute the environment or damage the ecology.

Introduced in the mid-1990s, lyocell fiber has been hailed as the most valuable product in the history of man-made fibers for nearly half a century. It has many excellent properties of both natural fibers and synthetic fibers. Lyocell is a green fiber. Its raw material is cellulose, which is inexhaustible in nature. The production process has no chemical reaction and the solvent used is non-toxic.

Lyocell fiber is a brand new spunlace non-woven material. It not only has the characteristics of comfort, good hand feel, and easy dyeing that natural fiber cotton has, but also has environmental protection advantages that traditional viscose fiber does not have. In the production process of viscose fiber, harmful gases such as carbon disulfide and hydrogen sulfide are released, which pollutes the environment.

Lyocell fiber is made of pulp formed by mashing renewable bamboo, wood, etc. as raw material. The advanced technology makes its solvent recovery rate as high as 99.7%, which is not only energy-saving, environmentally friendly, but also sustainable. Clothing made of this fiber not only has natural luster, smooth hand feeling, high strength, and basically does not shrink, but also has good moisture permeability and air permeability, and the effect of wool blended fabric is good.

Properties of Lyocell Fibers

(1) It has high dry and wet strength, with a dry-wet strength ratio of 85%.

(2) High swelling property: dry and wet volume 1:1.4

(3) Unique fibrillation characteristics, that is, Tencel fiber will split into fibrils along the fiber axis under the action of mechanical friction in the wet state, and a unique peach skin style can be obtained after processing.

(4) Good spinnability: it can be spun purely or interwoven with cotton, wool, silk, hemp, chemical fiber, cashmere and other fibers. It is suitable for spinning all kinds of machines and knitting yarns.

(5) 100% biodegradable, no pollution and no residue in the whole process of preparation and degradation. It is a new type of fiber that is very friendly to the environment.

Lyocell spunlace non-woven fabrics have the "comfort" of cotton, the "strength" of polyester, the "luxury beauty" of wool fabrics, and the "unique touch" and "soft drape" of silk, no matter in dry or wet state are extremely resilient. In the wet state, the wet strength of Lyocell spunlace non-woven fabric is far better than that of 100% cotton spunlace non-woven fabric.

Lyocell spunlace non-woven fabrics are 100% pure natural materials, coupled with environmentally friendly manufacturing processes, so that the lifestyle is based on protecting the natural environment, fully catering to the needs of modern consumers, and it is green and environmentally friendly, which can be called green in the 21st century. Non-woven material.

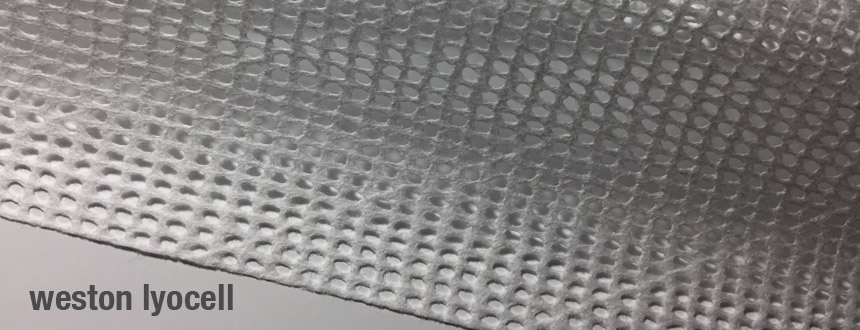

Weston lyocell fiber spunlace specification:

Max width: 3100mm

Grammage range: 35gsm-120gsm

MOQ:1000kgs